Medical high polymer splint is a kind of high polymer product made of high polymer polyurethane. It is an external fixation product used in fracture, sprain and strain, and it is an ideal fixation splint used before detumescence. Animal test and acute and chronic toxicology test showed that polyurethane for medical use had no toxicity, distortion and local irritation. It is suitable for the fixation of fracture patients and orthopedics.

Technical process

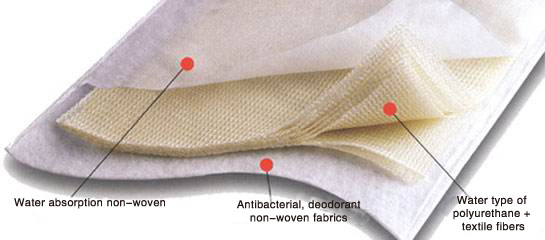

Excellent raw materials: made of imported fiber-based cloth dipped with organic environmental protection polyurethane adhesive.

Advanced technology: the base fabric woven with advanced technology has good plasticity and air permeability.

Suitable temperature: imported polyurethane compound, suitable exothermic temperature for fixed line, small shrinkage after fixed line.

Product characteristics

High strength: the strength of polymer splint is 5 times that of gypsum bandage, and it has good toughness. It can effectively resist the impact of external force and protect the injured part.

Light weight: polymer splint is 1 / 5 of the weight and 1 / 3 of the thickness of gypsum bandage, which can greatly reduce the burden of human activities.

The X-ray polymer splint has good permeability to X-ray, and the X-ray image is clear, which is helpful for doctors to understand the healing of the affected limb at any time during the observation process.

Good air permeability: the base cloth is mesh like, with excellent air permeability, 200 times of gypsum bandage, which can effectively prevent the skin from hot flashes, itching, peculiar smell and infection.

Fast hardening: the polymer splint solidifies in 3-5 minutes after being immersed in water, and achieves functional strength in 20-30 minutes. It can effectively prevent the displacement after fracture reduction, saving time for doctors and patients. And plaster bandages take about 24 hours to harden and bear weight.

It is easy to operate. It only needs warm water and no heating equipment. The operation can be completed in 3 minutes. Ordinary scissors can be removed.

Various specifications can be used for forearm, calf, thigh and other different parts, with various specifications and free choice.

Comfortable and safe: the exothermic temperature of polymer splint during curing is suitable, the shrinkage after curing is small, and the skin will not be tight, itchy and other uncomfortable symptoms. Patients feel more comfortable.

No pollution: the used products can be fully burned, and the incineration of materials will not produce any pollutants. Environmental protection!

Scope of application

It is used in orthopedics, hand surgery, plastic surgery for fracture, sprain, soft tissue, joint ligament tendon, etc. The utility model can be used as an auxiliary function appliance, a supporting appliance and an effective fixation of the injured part of the prosthesis.

Usage method

1. According to the specific situation of the affected part, select the polymer splint of appropriate specification and model

2. Open the packaging bag, take out the polymer splint, and fill the middle of the splint with a proper amount of water at room temperature (20-25 ℃), so that the middle material of the splint is in full contact with the water.

3. Take out the splint, squeeze it by hand or roll it with a dry towel to remove excess water

4. Place the inner thick non-woven cotton layer of the polymer splint close to the skin bracket at the position to be fixed, shape it according to the needs, and wrap it with gauze bandage or elastic bandage for fixation, with appropriate tightness.

5. The operation should be completed within 3-5 minutes. Within 20 minutes before the splint is hardened, the patient cannot move at will and can bear the weight 30 minutes later.

7. When the patients who need external fixation have skin trauma or need to operate for a longer time, the splint can be directly solidified without being immersed in water. After being wound and fixed with gauze bandage or elastic bandage, appropriate amount of water can be sprayed on the non-woven fabric of the thin outer layer to accelerate the hardening speed.

8. Cut the gauze bandage or elastic bandage splint to remove the polymer splint easily.

[precautions]

1. During the molding process, the product will be hot and hot. This is the product hardening. The human body can generally bear this temperature. The hardening time will not be very long. The temperature will drop in about 3-5 minutes.

2. The operation time is generally 3-5 minutes. If the immersion or operation time is extended, the shaping effect will be affected. The affected part shall not move at will within 30 minutes before the product is completely hardened.